简体中文

简体中文

The sizes of stainless steel cabinets vary. How does the Xulida glue pouring machine achieve precise glue pouring?

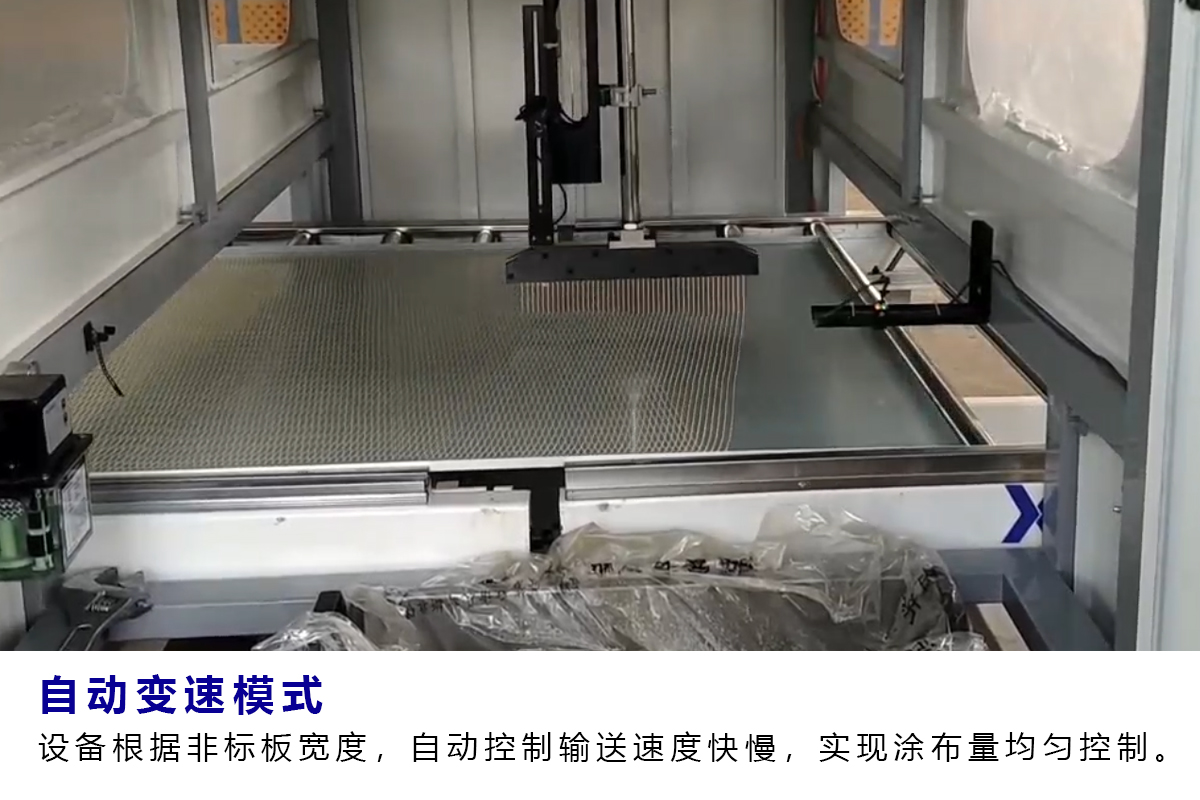

In the customized production of stainless steel cabinets, varying dimensions and non-standard components are common. This poses challenges for the glue application process, which requires uniform and continuous coating of sealants or structural adhesives. Traditional fixed-program glue applicators struggle to adapt, while Xulida's glue dispensing system successfully achieves precise and efficient flexible production through the following key technologies.

**The Core Lies in the Synergy of "Vision" and "Perception"**

The primary requirement for precise glue application is "knowing where to apply." This relies on advanced machine vision systems. Prior to operation, Xulida's glue applicator uses high-precision cameras to scan and locate the cabinet panel placed on the workbench. Through image recognition technology, the system quickly captures the panel's contour, corners, and pre-set reference points. Regardless of variations in the panel's size or shape, the vision system completes measurement and coordinate positioning instantly, transmitting accurate data to the motion control system. This provides a "map" for subsequent path planning.

**The "Brain" for Intelligent Path Planning**

Once the precise dimensions and position of the panel are obtained, the control "brain" of the glue applicator—the intelligent software system—comes into play. Operators need only select the panel type (e.g., door, side panel, base panel) in the system and set basic glue line parameters (e.g., line width, closed or open path). The system then automatically generates an optimal 3D glue application path that fully matches the current panel's dimensions. This process requires no manual reprogramming or teaching, truly achieving "one-click changeover" and significantly enhancing production efficiency and flexibility.

**The "Skilled Hand" of High-Dynamic Actuators**

With precise path instructions, the actuators must perfectly execute them. This demands that the motion system (typically a multi-axis robotic arm or precision gantry) possesses high repeatability positioning accuracy and dynamic response capability. Simultaneously, the glue dispensing control system is equally critical. It must maintain strict synchronization with the motion trajectory to ensure consistent glue output across different path segments, preventing glue buildup at corners or insufficient application on straight sections. By utilizing servo pumps combined with proportional valve technology, high-precision closed-loop control of glue output is achieved, thereby ensuring consistent glue line quality.

**Conclusion**

In summary, to address the challenge of varying sizes in stainless steel cabinets, Xulida's glue applicator integrates three core technologies: **"precise positioning via machine vision," "automatic path planning by intelligent software,"** and **"high-precision motion and glue dispensing control."** This deep integration successfully transforms the challenges of custom production into a standardized, automated process. It not only guarantees the quality of glue application for each uniquely shaped cabinet—ensuring tight seals, aesthetics, and durability—but also provides the production line with high flexibility, enabling rapid response to market demands for small batches and diverse varieties. This makes it a critical component in advancing the intelligent manufacturing upgrade of stainless steel cabinets.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist