简体中文

简体中文

**Liberating Hands, Intelligent Manufacturing: How Fully Automatic Glue Dispensing Production Lines Reshape Efficiency**

In the increasingly competitive manufacturing landscape, "reducing costs and enhancing efficiency" is a perpetual challenge. Among these, labor costs and management difficulties are particularly prominent. When traditional glue dispensing operations still rely on skilled workers manually holding applicators, bottlenecks in efficiency, fluctuations in quality, and worker fatigue become inevitable. So, how much valuable labor can the introduction of a fully automatic glue dispensing production line truly save? The answer goes far beyond a simple numerical substitution—it heralds a profound revolution in efficiency.

**The Leap from "Labor-Intensive Tactics" to "Unmanned Operation"**

Traditional manual glue dispensing involves complex steps: positioning, adjusting adhesive, dispensing, inspection... A single workstation often requires one or even multiple workers to maintain full concentration. Not only is their labor intensity high, but fatigue can easily lead to uneven application, broken lines, or inconsistent thickness, making it difficult to guarantee product yield.

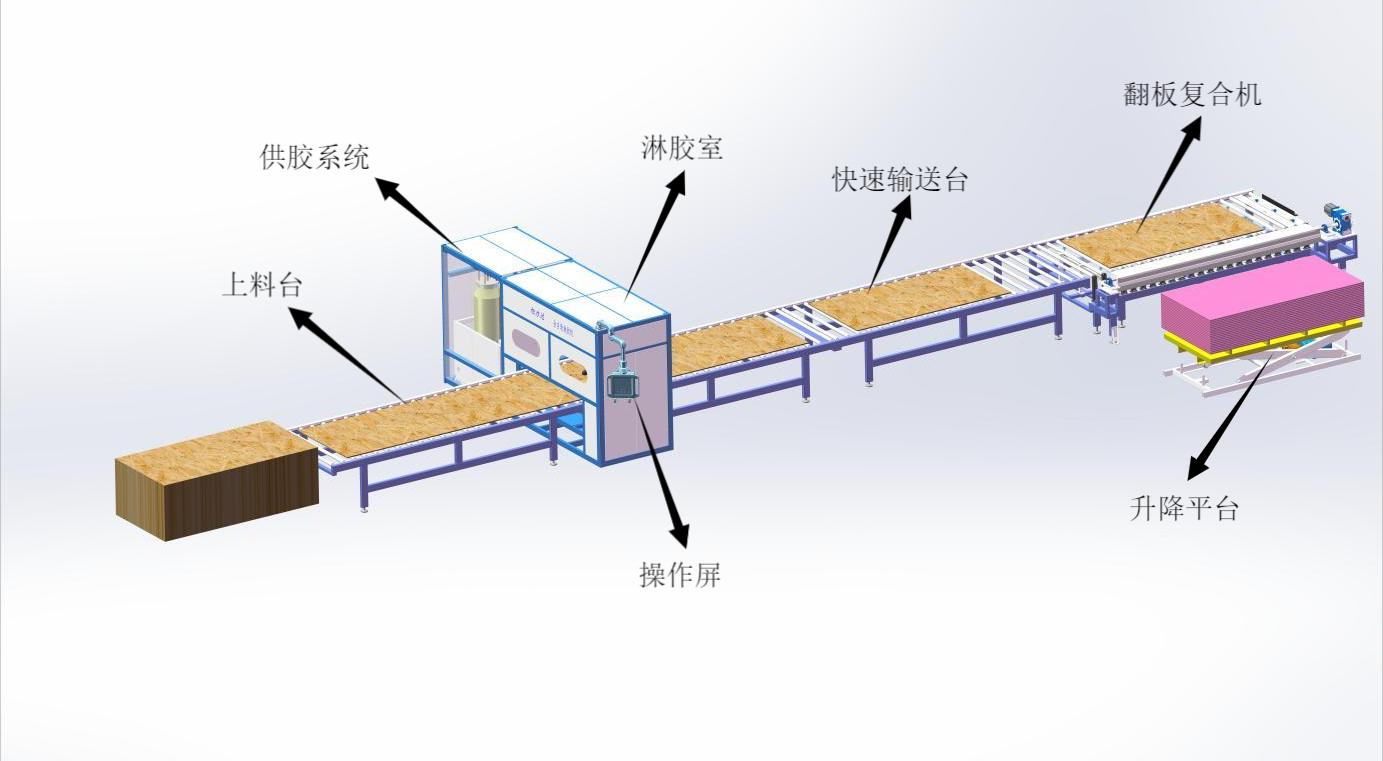

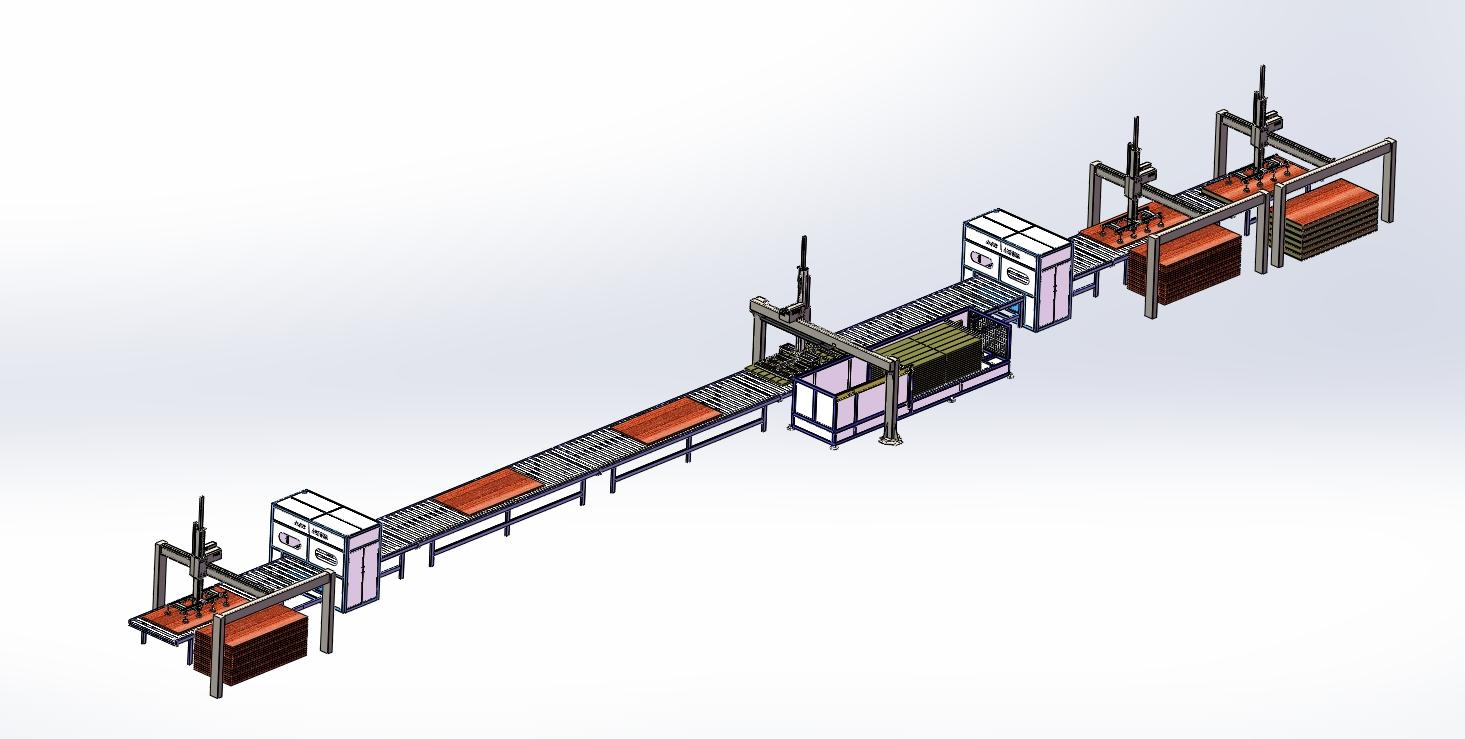

The fully automatic glue dispensing production line completely overturns this model. It integrates automatic feeding, precise positioning, constant-speed dispensing, real-time monitoring, and unloading into one seamless process, achieving truly "unmanned" flow operation. A production segment that originally required the close coordination of 3-5 workers now only needs **1 equipment operator** for patrol inspection, material replenishment, and emergency handling. **In terms of direct labor alone, a single production line can immediately save 2-4 skilled workers.** This is not just a saving on wages but also a significant reduction in hidden costs such as recruitment, training, and management.

**Transcending "Labor Saving" to Achieve "Superhuman" Efficiency**

However, saving direct operators is only the beginning of the story. The true value of fully automatic glue dispensing lines lies in achieving "superhuman" efficiency that is difficult for humans to match.

* **Multiplied Efficiency, Never Tires:** Robotic arms can dispense glue 24/7 at a constant speed and along optimal paths, significantly increasing production tempo and multiplying output capacity.

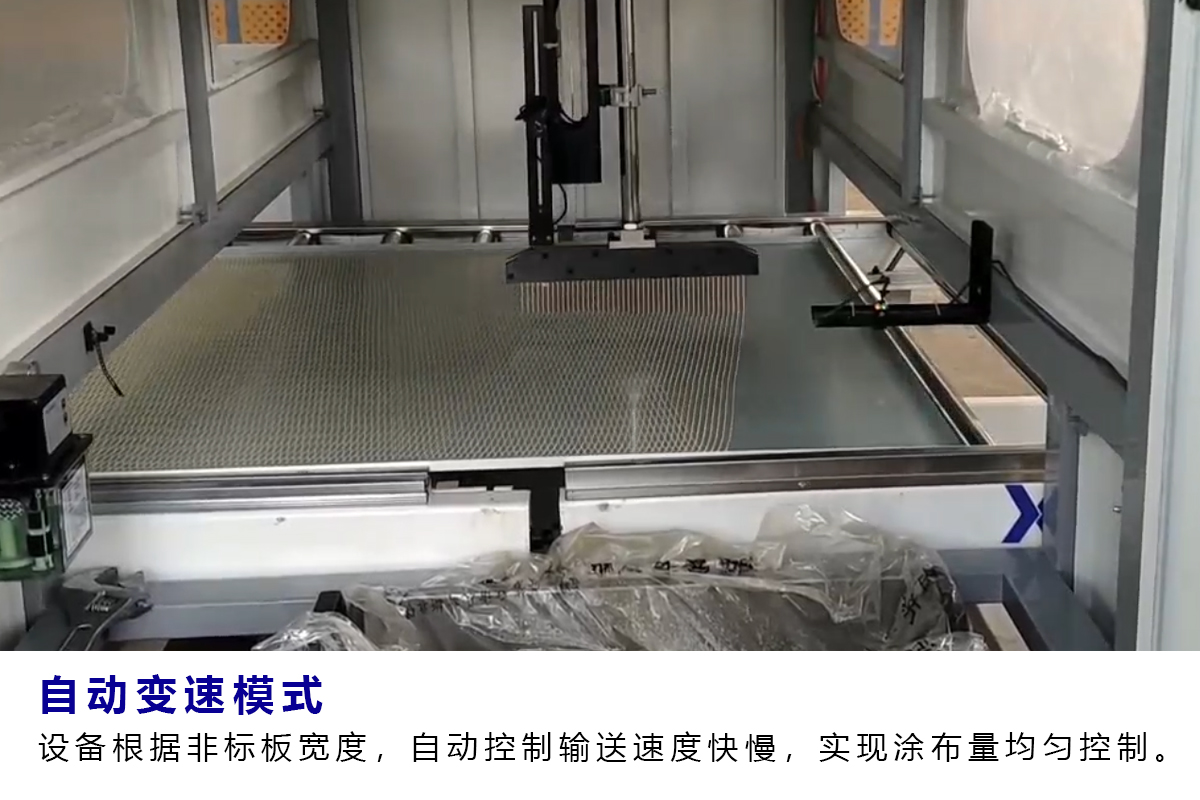

* **Consistent Quality, Farewell to Fluctuations:** With high-precision motion control systems and stable glue pressure control, it ensures consistent glue line width, neat edges, and freedom from bubbles or breaks for every single product. Product consistency and yield rates improve markedly, greatly reducing the labor required for subsequent repairs and rework.

* **Material Savings, Further Cost Reduction:** Precise control over the amount of adhesive dispensed avoids the drips and waste inherent in manual operations, directly saving valuable adhesive materials.

**Deeper Liberation of "Labor": From Operator to Manager**

The significance of full automation lies further in redefining and upgrading the value of "human labor." Employees reassigned from replaced tasks no longer need to engage in repetitive, monotonous, and potentially hazardous manual work. They can be retrained to transition into roles such as equipment supervisors, quality inspectors, or technical maintenance personnel—evolving from "manual laborers" to "knowledge-based managers." This not only optimizes the allocation of human resources but also enhances employees' professional skills and job satisfaction.

**Conclusion**

The savings delivered by a fully automatic glue dispensing production line far exceed the salaries of a few workers. It saves the quality losses caused by fatigue and variability, the market opportunities missed due to inefficiency, and the management dilemmas arising from labor shortages. It is a revolution that thoroughly liberates human effort from repetitive tasks, redirecting "labor" into more creative and managerial work, thereby achieving a leap forward in the overall competitiveness of the enterprise.

Investing in full automation is, in essence, investing in a more stable, efficient, and resilient future.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist