简体中文

简体中文

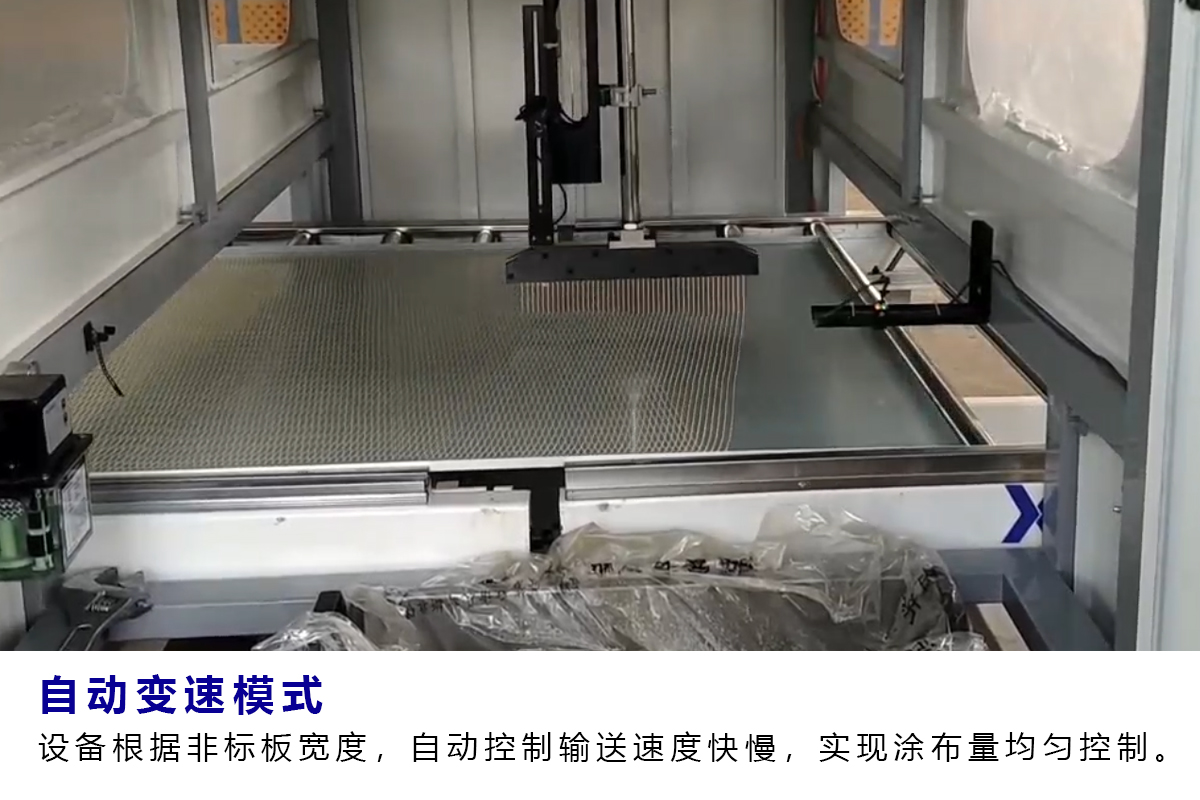

How can a fully automatic glue applicator maintain a consistent glue output when the board sizes are different?

When faced with panels of varying sizes, ensuring consistent adhesive discharge in a fully automatic glue spreading machine relies on upgrading from a traditional "fixed-path" output mode to a closed-loop control mode characterized by "dynamic following and intelligent regulation." This is primarily achieved through the synergy of the following key technologies:

**1. Vision Recognition and Precision Positioning System:**

This is the prerequisite for accurate glue application. Using high-resolution cameras or laser sensors, the machine quickly scans the panel upon entry to accurately identify its contour, dimensions, and exact position on the worktable. This data is transmitted in real-time to the main control center, enabling it to plot a precise glue application path that perfectly matches the panel's edges, preventing adhesive waste or gaps caused by misalignment.

**2. Dynamic Parameter Matching and Flow Control:**

The main control center contains a rich set of process recipes. Once the vision system identifies the current panel's size (e.g., length, width), the system automatically calls up or calculates the corresponding spreading parameters. This includes:

* **Dispensing Valve On/Off Logic:** Precisely controls the timing of valve opening and closing, ensuring adhesive is only applied to the panel surface without buildup or stringing at the path ends.

* **Precise Adjustment of Pump Flow:** Using servo motor-driven precision gear pumps or metering pumps, the output flow is adjusted in real-time and seamlessly based on the panel size (primarily length changes) and the preset glue line specifications (e.g., width, thickness). For longer panels, the system maintains a stable flow rate; for shorter panels, it reduces the flow accordingly, ensuring a constant adhesive amount per unit length.

**3. Closed-Loop Real-Time Feedback and Compensation System:**

This is the core technology ensuring highly consistent discharge. The system incorporates high-precision flow meters and pressure sensors in the adhesive discharge pipeline, forming a closed-loop control circuit.

* **Flow Monitoring:** The flow meter continuously monitors the actual discharge volume and feeds this data back to the controller.

* **Real-Time Comparison and Correction:** The controller compares the measured flow rate with the set value on a millisecond basis. Upon detecting even a minor deviation (potentially caused by adhesive viscosity changes, pump wear, or pipeline pressure fluctuations), it immediately issues commands to dynamically adjust the pump speed or valve opening, providing real-time compensation. This ensures the actual adhesive discharge remains stable at the target setpoint from the first panel to the last.

**In summary,** modern fully automatic glue spreading machines have evolved beyond simple mechanics performing repetitive actions. Through the integrated intelligent solution of "Vision Recognition & Positioning, Automatic Parameter Matching, and Closed-Loop Real-Time Control," they successfully incorporate the variable of inconsistent panel sizes into a controllable process, ultimately achieving consistent, stable, and efficient adhesive application on varying substrates

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist