简体中文

简体中文

consumer electronics, automotive, medical devices, new energy, etc.). Their core advantages are mainly reflected in the following aspects

**Advantages of Fully Automatic Glue Dispensing Machines**

Fully automatic glue dispensing machines offer significant advantages over traditional manual or semi-automatic dispensing/coating methods, making them indispensable key equipment in modern precision manufacturing industries (such as :

1. Extreme Precision and Consistency**

* **Precise Metering**: High-precision metering pumps and closed-loop control systems ensure highly consistent shot volume and mixing ratio (for two-component adhesives) for every drop, with minimal error (can reach within ±1%).

* **Precise Path and Positioning**: Controlled via CNC programs or multi-axis robotic arms, the glue path trajectory, start/stop points, and dispensing shape (lines, surfaces, circles, etc.) can be accurately reproduced without human variation.

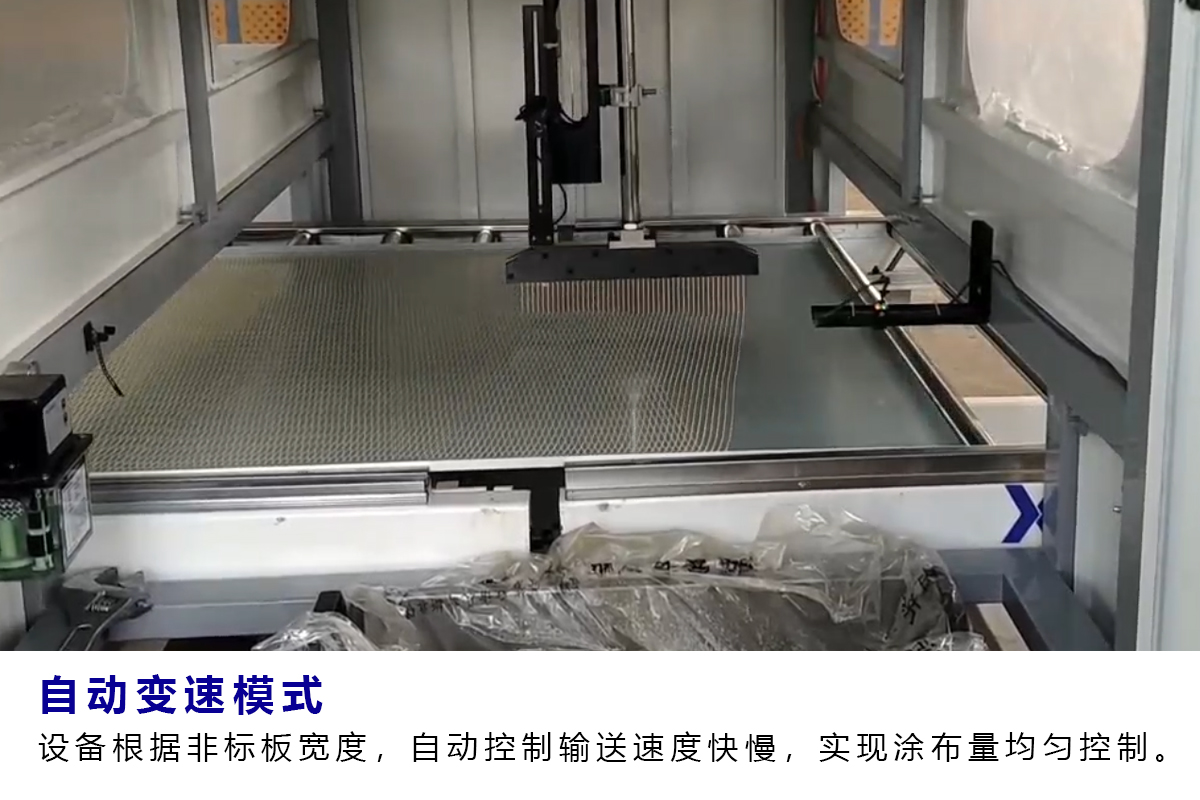

* **Stable Bead Profile**: Constant pressure, temperature, and dispensing speed ensure uniformity in the glue bead's morphology (width, thickness).

### **2. Significantly Improved Production Efficiency**

* **High-Speed Operation**: The machine can operate continuously at high speed 24/7, with movement and dispensing speeds far exceeding manual capabilities.

* **Reduced Auxiliary Time**: Eliminates manual tasks like adhesive preparation, weighing, and cleaning, enabling continuous production.

* **Parallel Processing**: Can integrate multiple dispensing valves or synchronize with conveyor lines, allowing simultaneous multi-station operation or inline production.

### **3. Substantial Reduction in Overall Costs**

* **Material Costs**: Precise control drastically reduces adhesive waste and material loss due to defective products.

* **Labor Costs**: One machine can replace multiple skilled workers, reducing dependence on labor and associated training/management costs.

* **Quality Costs**: High consistency and low defect rates minimize rework, scrap, and after-sales costs, enhancing brand reputation.

### **4. Superior Process Complexity and Flexibility**

* **Complex Patterns**: Easily achieves automated coating of curves, 3D paths, and irregular areas (e.g., smartphone bezels, circuit boards), which is difficult manually.

* **Parametric Programming**: Quick switching between different products by calling different programs, adapting to flexible production of small batches and high variety.

* **Multiple Processes**: Can perform various dispensing processes such as **line coating, area coating, sealing, filling, and dam building**, making it a multi-purpose machine.

### **5. Excellent Product Quality and Reliability**

* **Eliminates Human Error**: Avoids quality fluctuations caused by worker fatigue, skill differences, or mood swings.

* **Controllable and Traceable Process**: All process parameters (pressure, speed, flow rate, time) are recorded and monitored, facilitating quality traceability and process analysis.

* **Enhances Product Performance**: Uniform and consistent adhesive layers ensure better sealing, thermal conductivity, insulation, and structural strength.

### **6. Improved Working Environment and Safety**

* **Occupational Health**: Frees workers from repetitive manual labor and potentially harmful chemical fume environments.

* **Production Safety**: Reduces risks of equipment damage or personal injury due to improper operation.

* **Clean Environment**: Automated production sites are tidier and more organized, aligning with modern factory 6S/7S management standards.

### **7. Ease of Integration and Intelligence**

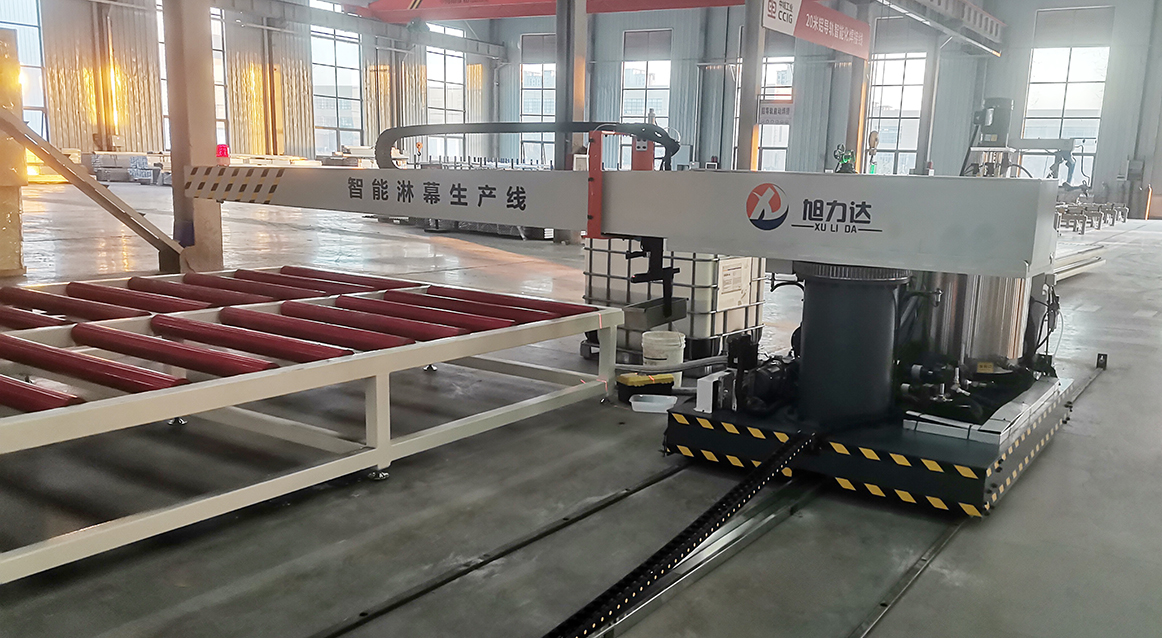

* **Production Line Integration**: Can be seamlessly integrated with PLCs, MES systems, loading/unloading robots, vision positioning systems, curing ovens, etc., to create fully automated smart production lines.

* **Intelligent Compensation**: When integrated with vision systems, it can automatically recognize product position deviations and perform path compensation, accommodating incoming part tolerances.

* **Data-Driven Management**: Production data (quantity, time, consumables) can be uploaded to servers for production management and optimization.

---

### **Summary**

The core value of fully automatic glue dispensing machines lies in transforming **"experience-dependent" manual operations** into **"data-driven" precision manufacturing processes**. They are not merely tools for improving efficiency and saving costs but are also critical infrastructure for ensuring **consistent quality in high-end products, realizing complex processes, and driving factory digitalization and intelligent upgrades**. For enterprises pursuing high reliability, high precision, and规模化 (scaled) production, investing in fully automatic glue dispensing machines is an inevitable choice.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist