简体中文

简体中文

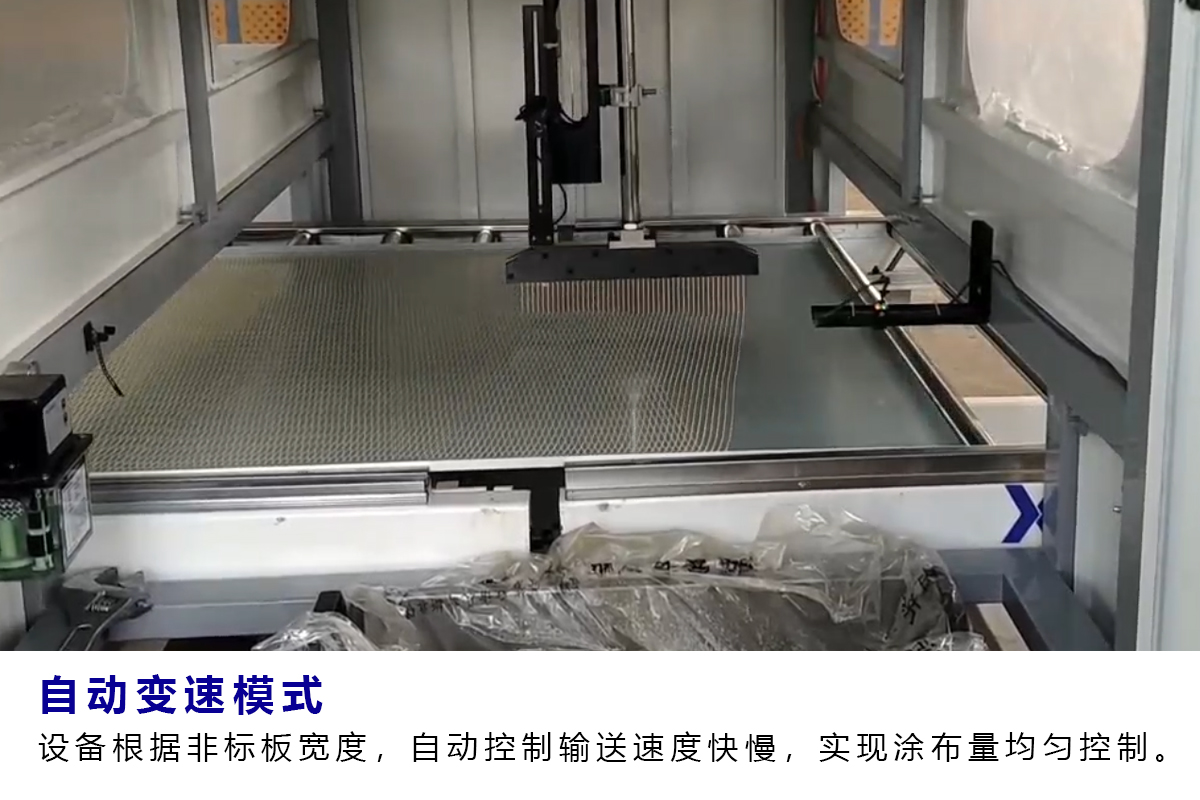

Benefits of Glue Spreading Machines for Honeycomb Panel Lamination

Glue spreading machines (or curtain coating equipment) offer significant advantages in the production of honeycomb panels (such as aluminum honeycomb panels, paper honeycomb panels, etc.), improving both product quality and production efficiency.

1. Uniform Glue Layer, High Bonding Strength

Even Coverage: The machine precisely controls glue application, forming a continuous and uniform adhesive film on the honeycomb core or panel, avoiding uneven distribution caused by traditional spraying or roller coating.

Excellent Penetration: The adhesive fully penetrates the honeycomb cell walls, enhancing bonding strength between the core and panels while reducing delamination risks.

2. High Production Efficiency

Fast Coating: Enables high-speed continuous operation, significantly improving efficiency compared to manual or semi-automatic methods.

Reduced Labor Dependency: Automated control minimizes human error and reliance on skilled workers.

3. Adhesive Savings

Precise Glue Control: Flow control systems (e.g., metering pumps) adjust glue volume accurately, reducing waste and costs.

No Splatter Loss: Unlike spraying, curtain coating minimizes adhesive misting and overspray.

4. Wide Applicability

Multiple Adhesives: Compatible with epoxy, polyurethane, acrylic, and other adhesives to meet strength, weather resistance, or flexibility requirements.

Adaptability to Complex Structures: Adjustable spray heads ensure even coating on irregular honeycomb cores or curved panels.

5. Improved Product Consistency

Stable Process: Automated systems ensure uniform glue thickness and positioning for each panel, eliminating quality variations from manual work.

Fewer Air Bubbles/Voids: Even adhesive distribution fills honeycomb structures effectively, reducing defects.

6. Environmental and Safety Benefits

Lower VOC Emissions: Closed systems can integrate solvent recovery to reduce volatile organic compound release.

Safer Operation: Minimizes direct contact with adhesives, reducing health risks.

7. Easier Post-Processing

High Flatness: Laminated panels have fewer uneven surfaces, reducing the need for grinding or correction.

Faster Curing: Uniform glue layers promote thorough curing, shortening production cycles.

Applications

Aluminum Honeycomb Panels: Used in building facades, rail vehicle interiors, etc.

Paper Honeycomb Panels: For packaging, furniture, lightweight partitions, etc.

Other Composites: Plastic honeycomb, metal-clad panels, etc.

Key Considerations

Adhesive Selection: Must match core (aluminum, paper, PP, etc.) and panel (aluminum sheet, steel, composites) materials.

Maintenance: Regular nozzle cleaning prevents clogging.

Process Optimization: Adjust glue viscosity, spreading speed, and temperature for best results.

By using glue spreading technology, honeycomb panels achieve optimized performance in lightweighting, strength, and flatness while lowering overall production costs, making it a preferred method for modern composite panel manufacturing.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist