简体中文

简体中文

Advantages of Glue Spreading Machine for Composite Exterior Wall Insulation Panels

The glue spreading machine composite process is an efficient production method for exterior wall insulation panels, primarily used to bond insulation materials (such as EPS, XPS, rock wool, etc.) with decorative layers (such as calcium silicate boards, cement fiber boards, etc.) using adhesives, forming integrated insulated decorative panels. Compared to traditional construction methods, the glue spreading machine composite process offers the following advantages:

I. Core Advantages of the Glue Spreading Machine Composite Process

1. High Production Efficiency, Suitable for Mass Production

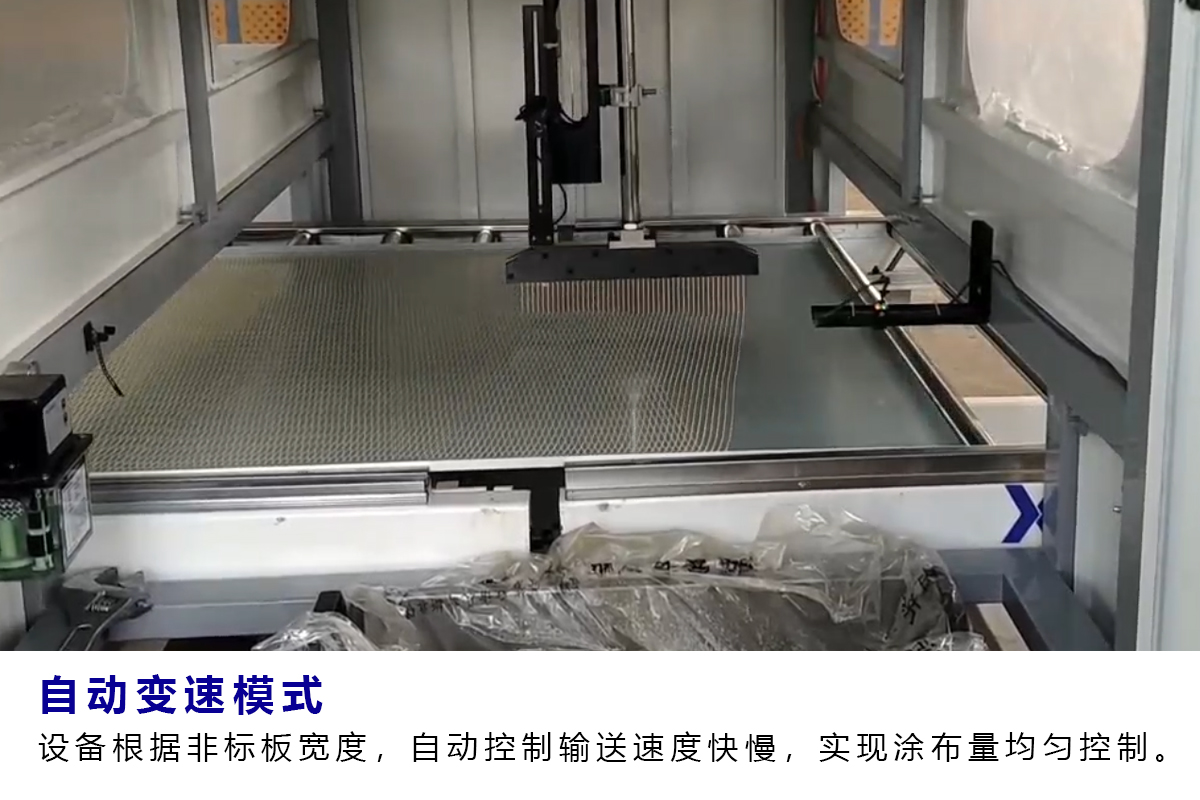

Automated Glue Application: The glue spreading machine precisely controls adhesive volume and ensures even coating, improving efficiency by 3–5 times compared to manual application.

Continuous Composite Process: Can be integrated with production lines for rapid bonding of insulation panels and decorative layers, making it ideal for large-scale orders.

2. High Bonding Strength and Stable Quality

Uniform Adhesive Layer: The high-pressure spraying or roller coating ensures excellent adhesive penetration, reducing the risk of hollowing or detachment.

Minimized Human Error: Eliminates uneven glue application caused by manual work, ensuring consistent bonding quality.

3. Material Savings and Cost Reduction

Precise Adhesive Control: Reduces adhesive waste and lowers production costs.

Fewer Post-Installation Repairs: High composite quality reduces maintenance costs after installation.

4. Enhanced Environmental Friendliness

Lower VOC Emissions: Uses low-formaldehyde or solvent-free adhesives, complying with environmental standards.

Dust-Free Production: Factory prefabrication reduces on-site dust pollution compared to traditional construction.

5. Compatibility with Various Material Combinations

Multiple Decorative Finishes: Can be combined with finishes like stone-like coatings, aluminum panels, and ceramic thin plates.

Adaptable to Different Insulation Cores: Suitable for EPS, XPS, rock wool, PU, and other insulation materials.

II. Comparison: Glue Spreading Machine Composite Panels vs. Traditional Construction

| Comparison Factor | Glue Spreading Machine Composite Panels | Traditional On-Site Construction |

| Production Efficiency | High (factory prefabrication, quick installation) | Low (manual layer-by-layer construction) |

| Bonding Quality | Uniform and high-strength, less hollowing | Depends on worker skill, prone to hollowing |

| Construction Time | Short (direct installation) | Long (multiple steps required) |

| Environmental Impact | Excellent (closed factory production) | Moderate (dust and adhesive pollution on-site) |

| Cost | Higher initial equipment investment but long-term labor savings | High labor costs, more material waste |

| Applicable Scenarios | Ideal for standardized buildings and large-scale projects | Suitable for complex designs or small-scale projects |

III. Applications of Glue Spreading Machine Composite Insulation Panels

1. Prefabricated Construction: Suitable for prefabricated exterior wall panels, accelerating construction speed.

2. Large Commercial/Residential Projects: Standardized production ensures quality and meets deadlines.

3. Energy-Efficient Retrofits: Can be directly installed for building renovation projects.

4. High-End Curtain Wall Systems: Combined with metal, stone, or other finishes to enhance architectural aesthetics.

IV. Future Development Trends

Smart Upgrades: AI vision inspection for automatic glue adjustment, improving yield rates.

Eco-Friendly Adhesives: Development of formaldehyde-free and water-based adhesives for higher environmental standards.

Customized Finishes: Supports digital printing, stone-like textures, and other high-end finishes.

Conclusion

Glue spreading machine composite exterior wall insulation panels offer significant advantages in production efficiency, bonding quality, environmental performance, and cost control, making them particularly suitable for large-scale construction projects and **prefabricated buildings. This technology represents an important direction for the future development of exterior wall insulation systems.

consumer electronics, automotive, medical devices, new energ

consumer electronics, automotive, medical devices, new energ

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

Consequences of Inaccurate Adhesive Ratio in Fully Automatic

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

**Liberating Hands, Intelligent Manufacturing: How Fully Aut

How can a fully automatic glue applicator maintain a consist

How can a fully automatic glue applicator maintain a consist